Inventory management is a critical aspect of any manufacturing business, whether you’re a small startup or a medium-sized enterprise. Properly tracking your inventory ensures that you have the right amount of raw materials and finished products at all times, preventing overstocking or understocking issues. While there are advanced inventory management systems available, many businesses begin managing their inventory using spreadsheets. In this article, we’ll provide five important tips to efficiently track manufacturing inventory only using spreadsheets.

Get a jump start with this Free Google Sheets template!

1) A Detailed Inventory Spreadsheet is Critical

The foundation of successful inventory management using spreadsheets is a well-structured and detailed inventory spreadsheet. This document should contain several key pieces of information:

- Item Name: Clearly label each inventory item to avoid confusion.

- Description: Provide a brief description of the item, including any specific details or characteristics.

- SKU (Stock Keeping Unit): Assign a unique SKU to each item for easy tracking and reference.

- Purchase Cost: Record the cost of acquiring each item, which is crucial for calculating the overall value of your inventory. You may want to include multiple acquisition sources and their associated prices for more robust supply chain management.

- Selling Price: Knowing the selling price helps with margin calculations and pricing strategies.

- Quantity on Hand: This is perhaps the most crucial aspect; it tracks how many of each item you currently have in stock.

To maintain the integrity of your spreadsheet, make sure to update it regularly. Depending on your sales and production velocity, this could be as much as several times a day.

2) Implement FIFO and LIFO Inventory Methods

Managing inventory costs and minimizing waste is essential for profitability. Two popular inventory management methods are FIFO (First-In, First-Out) and LIFO (Last-In, First-Out). These methods are especially important for businesses dealing with perishable goods or items with limited shelf life.

It is also important if you purchase products or materials in batches where the price fluctuates regularly. In these cases, it is critical to know the purchase price for each batch to ensure the desired profit margins are maintained as different batches are used up.

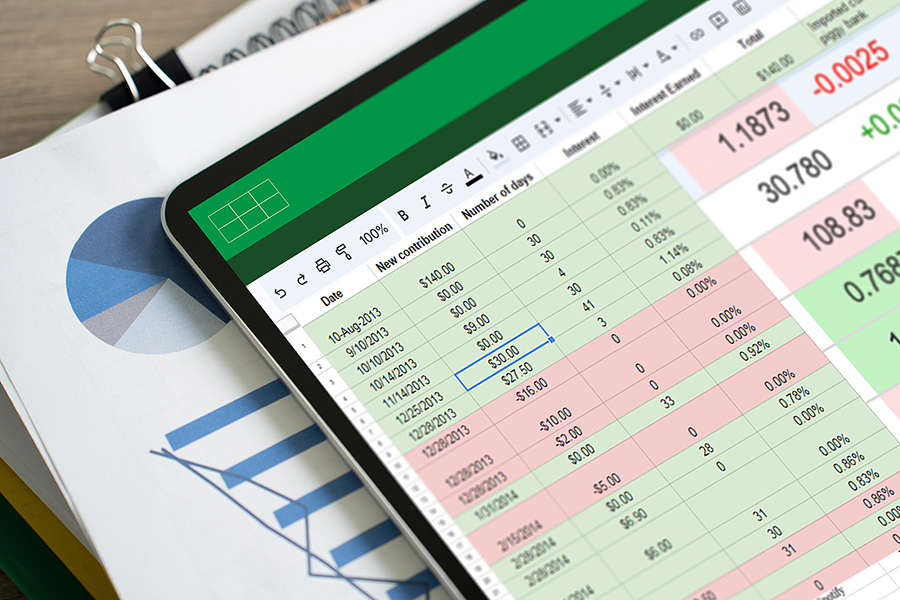

To implement these methods in your spreadsheet, create columns for the date of purchase or manufacture and the date of sale or usage. This allows you to see which items are the oldest (FIFO) or the newest (LIFO). By applying these methods, you can prioritize the sale of older stock to minimize obsolescence.

3) Set Up Conditional Formatting for Alerts

Conditional formatting is a powerful feature in spreadsheets that can be used to create visual cues and alerts based on specific conditions. In your inventory spreadsheet, you can set up conditional formatting to automatically highlight cells when certain thresholds or conditions are met. For instance:

- Low Stock Alerts: If an item’s quantity falls below a predetermined threshold, the cell could change to a red color, serving as a clear visual signal that it’s time to reorder.

- Expiry Alerts: For perishable items, you can use conditional formatting to highlight items that are approaching their expiration date, ensuring they are used or sold before they go to waste.

These alerts improve the efficiency of your inventory management and help ensure that you don’t run out of essential materials or products unexpectedly.

Related: How to Build a Project Management Template using Google Sheets

4) Track Sales and Demand

To effectively manage manufacturing inventory, it’s essential to keep a close eye on sales and demand patterns. Create a separate sheet within your spreadsheet to record sales data, including details such as:

- Date of Sale: Record when each sale occurred to identify patterns and seasonality.

- Quantity Sold: Keep track of how many units were sold for each item.

- Customer Information: If applicable, note which customers purchased specific items to identify potential bulk buyers or regular customers.

By analyzing this data, you can identify trends, seasonality, and changes in customer demand. This information will help you make informed decisions about how much to reorder, when to do it, and which items to prioritize. It can also inform your production schedule, ensuring that you’re prepared for fluctuations in demand.

5) Implement Regular Audits and Cycle Counts

No matter how well-structured your spreadsheet is, it’s essential to back it up with regular physical audits and cycle counts. This practice helps ensure the accuracy of your inventory and reduces discrepancies between the physical count and the recorded count. Here are some important details regarding audits and cycle counts:

- Frequency: Schedule routine checks according to your business needs. This could be daily, weekly, monthly, or on another schedule that suits your operations.

- Documentation: Keep thorough records of your audits, noting any discrepancies and the actions taken to rectify them. This documentation is crucial for accountability and improving your inventory management process.

- Employee Training: Make sure your employees are well-trained in the audit process to maintain accuracy. Educate them on the importance of maintaining precise inventory records and tracking any discrepancies.

Effective manufacturing inventory management is vital for reducing costs, improving efficiency, and satisfying customer demand. When just getting started (or any time budgets are tight), small and medium-sized businesses can use spreadsheets to keep their inventory in check. It’s important to keep in mind that while spreadsheets provide a cost-effective and accessible solution for many businesses, they come with a trade-off. Maintaining up-to-date spreadsheets requires constant vigilance and manual work. As your business grows, this process can become an increasingly daunting task. Check out this article to see if your growing pains are telling you it’s time to move on from spreadsheets and manual processes.

If you’re ready to upgrade from manual processes, or your current software budget needs some relief, PrismHQ provides a solution between spreadsheets and the expensive, feature-bloated software that dominates the market today. Don’t hesitate to reach out with questions or to request a demo. Our mission is to provide you with the tools you need to get back to growing your business, and not just running it!

What should I do now?

Below are three ways you can continue your journey to increase efficiency and boost growth at your company:

Download our free Technology Assessment and see if you’ve outgrown your current technology and processes.

Follow us on LinkedIn, Facebook, and X (Twitter) for bite-sized insights on manufacturing technology, software, processes, and more.